The difference in zirconia sintering furnaces is not only based on brand and price. Heating elements, sintering curves, and temperature control accuracy are all important. So what kind of zirconia denture sintering furnace is best for your dental experiment?

The motor design and performance of the furnace is to set the required sintering parameters as the zirconia material increases. Most zirconia materials are sintered below 1550°C (4°C-10°C per minute), but some zirconia material manufacturers will A lower or higher temperature is recommended.

The right temperature

It should be noted that recent studies have shown that the zirconia material produces the maximum strength at about 1500°C (depending on the accuracy of the furnace temperature). Fluctuations around 150°C will cause the growth of crystal grains and lead to a decrease in the strength of the zirconia material. Studies have shown that when the strength rises from 1280 MPa at 1500°C to 1600°C, the strength at this time will drop to 980 MPa. It is only 600 MPa at 1700°C.

In addition, higher temperatures may reduce the stability of the material, and cause zirconia cracking, which is only a physical change. If the temperature is too high, the transparency of the material will also decrease. High is not always the best! It is essential to follow the sintering curve recommended by the manufacturer. As long as the quality of the manufacturer's material is too hard, most zirconia materials can reach the ideal sintered state at a temperature of 1550°C.

Heating element

Kejia electric furnace provides the best quality pollution-free silicon molybdenum rods from the market. It is specifically for sintering zirconia. The highest temperature can reach 1800℃, and the life is long. Molybdenum disilicide heating element (Mosi2) is an electric heating element composed of Mosi2 material. It is used in high temperature oxidizing atmosphere. There is a layer of glass film on the surface, this layer of glass film can protect the silicon molybdenum rod from being oxidized, so this silicon molybdenum rod has a unique high-temperature oxidation resistance.

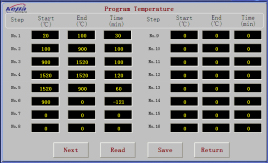

Temperature control program

If you use zirconium blocks from multiple manufacturers, or you are looking for different results, you would even want to buy a furnace with a sintering curve. More importantly, there must be multiple temperature ranges for setting. The following is Kejia electric furnace KJ-M1700-DL zirconia crystallization furnace (16 temperature zones and 16 sintering curves can be set in total).

Safety performance

All the characteristics of the zirconia crystallization furnace can be provided by the manufacturer, and perhaps the most important is the safety issue. After all, the furnace can easily reach a high temperature and will keep it warm for a period of time during the high temperature stage. Manufacturers will use high ampere power. Regarding the safety of operators and laboratories, be sure to look for CE certification marks. If you are about to buy a stove, please refer to this article, I hope you can buy an efficient and safe stove as soon as possible.

E-mail:web@kejiafurnace.com

E-mail:web@kejiafurnace.com

Tell:+(86) 18037178440

Tell:+(86) 18037178440

Whatapp:+(86) 180-3717-8440

Whatapp:+(86) 180-3717-8440

Address:Room 1505, Building 9, No. 26 Dongqing Street, Zhengzhou High-tech Industrial Development Zone

Address:Room 1505, Building 9, No. 26 Dongqing Street, Zhengzhou High-tech Industrial Development Zone