A brief discussion on Tsinghua University customer’s fluidized bed-chemical vapor deposition system

Fluidized bed-chemical vapor deposition (FB-CVD) technology is a cross-application of chemical fluid chemistry and material chemical vapor deposition preparation technology. It has important applications in the preparation of nuclear fuel coated particles (Coated fuel Particles, CP). It has long occupied a key position in the preparation of high-temperature gas-cooled reactor nuclear fuel elements.

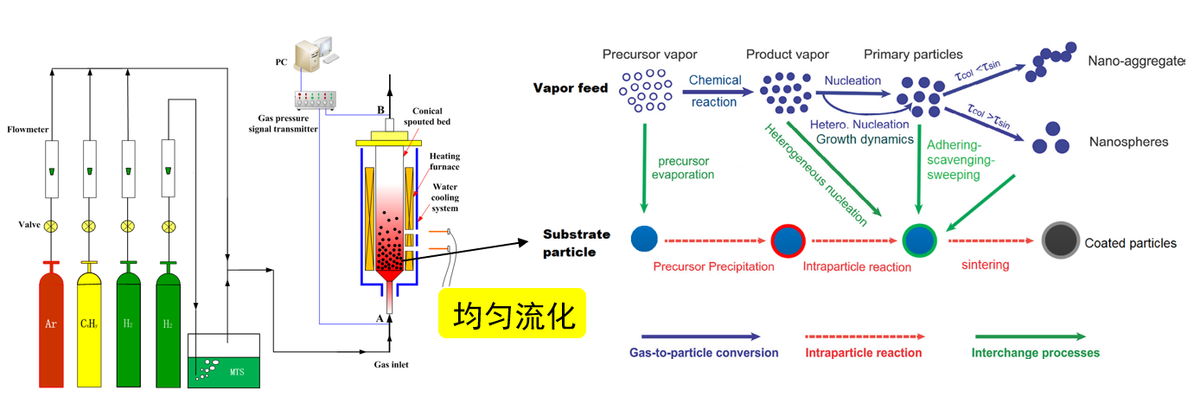

The basic principle of FB-CVD is that in the fluidized bed, the matrix particles are fluidized under the action of the fluidizing gas flow, and the gaseous reactants (or the heated vapor of the liquid precursor) enter the fluidized bed in the form of carriers. A chemical reaction occurs in the high-temperature area, forming ultra-fine powder particles or forming a film deposited on the surface of the particles. This technology originated in the field of nuclear energy and was initially applied to the coating of ceramic spherical nuclear fuel cores. Now it has gradually expanded to fields such as carbon nanotube preparation, polysilicon preparation, catalytic carrier and powder modification.

Application:

1.Fluidized bed CVD system for waste recycling:

E-mail:web@kejiafurnace.com

E-mail:web@kejiafurnace.com

Tell:+(86) 18037178440

Tell:+(86) 18037178440

Whatapp:+(86) 180-3717-8440

Whatapp:+(86) 180-3717-8440

Address:Room 1505, Building 9, No. 26 Dongqing Street, Zhengzhou High-tech Industrial Development Zone

Address:Room 1505, Building 9, No. 26 Dongqing Street, Zhengzhou High-tech Industrial Development Zone