Tel Number

180-3717-8440

Company Statement" Zhengzhou KJ Technology Co., Ltd. " belongs to the international business department of KJ Group. Starting today, the company will continue the international business contract signed or currently being performed by " Zhengzhou Kejia Furnace Co., Ltd. " See details >>

Description:

ALD PECVD System is a tube furnace with 80mm diameter alumina tube, vacuum pump and six channels mass flow meters gas flowing system. It can mix 1-6 types of gases for PECVD or diffusion.

| Model | KJ-PECVD | |

| Part I: Standard Parts | ||

|

Tube Furnace

|

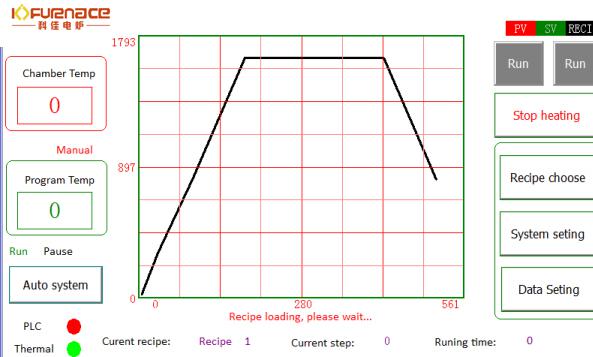

Display | LCD Touch Screen |

| Continuous Woking Temp. | ≤1100℃ for 1st zone ≤1100℃ for 2nd zone ≤1600℃ for 3rd zone |

|

| Heating Rate | Suggestion: 0~10℃/min | |

| Temperature Zone | 220mm+220+220mm Customizable | |

| Heating Element | Sic heater and MoSi2 heaters | |

| Thermocouple | N type and B type | |

| Temperature Control Accuracy | ±1℃ | |

| Tube Size | 80x1600mm (OD x minimum L) Approx. Customizable | |

| Material: alumina | ||

| Temperature Control | PID automatic control via SCR power control | |

| Tilt function | 0-15 degree (it is not suggested to work in tilt function at 1100C, since the MoSi2 heating element may broken easily. It will become soft at high temperature, pls be kindly noted.) |

|

| Heating curves | 30 steps programmable | |

| Vacuum Flange |

Stainless Steel vacuum flange with valve Right side flange is sliding type. And the flange will be water cooling type. |

|

|

Vacuum Pump

|

Molecular Pump System |

Ultimate vacuum:6.7*10-5 Torr. Include digital vacuum gauge |

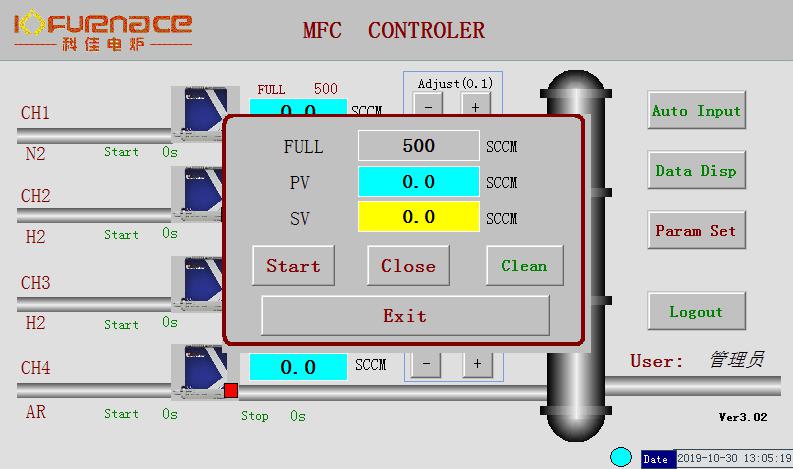

| Mass Flow Meters (LCD Touch Screen) | Six precision mass flow meters : MFC Accuracy is: ±1.5% F.S. MFC 1 for Ar : Gas flow range depends on customer’s requirement MFC 2 for N2 : Gas flow range depends on customer’s requirement MFC 3 for O2 : Gas flow range depends on customer’s requirement MFC 4 for C2H2: Gas flow range depends on customer’s requirement MFC 5 for CH4: Gas flow range depends on customer’s requirement MFC 6 for H2: Gas flow range depends on customer’s requirement (above flow range is only for reference, Pls confirm gas flow range before palce order. ) One gas mixing tank is installed on bottom case with 6 stainless steel needle valves is installed on left side of bottom case to control 6 type gases mixing manually. LCD Touch Screen (designed by kejia, with Kejia Logo) for MFC is as below:   |

|

|

(this valve is not supplied by us)ALD valve |

Two ALD valves with pulse controller (min 10 ms duration ) And connect to touch screen  |

|

| Liquid-Vapor Generator | Automatic liquid vapor generator is included and connect to ALD valve |

|

|

1.7MHZ ultrasonic Atomization  |

Equipped with a 1.7MHz ultrasonic atomizer, the liquid can be atomized into liquid particles and introduced into a tube furnace. 20VAC, 1.7MHz ultrasonic atomizer • The liquid tank comes standard with 316 stainless steel,and sealed with a fluorine rubber seal; • Atomization amount can be set from 1 to 8, and the amount of atomization can be controlled by adjusting the size of the gear; • It can realize two functions of continuous operation atomization and regular operation atomization. The timing can be adjusted from 30 minutes to 180 minutes (adjust the gear every 30 minutes). |

|

| Liquid injection system | • A standard set of liquid injection pumps for automatic liquid feeding • The syringe pump is equipped with a plastic syringe with a maximum volume of 60ml for holding liquids; • Syringe pump speed adjustment range: 0.004ml / min—70ml / min |

|

| Water Chiller | Used to cool down water cooled flange and vacuum pump. |

|

Rotary Tube Pyrolysis Furnace - For Engineering Plastic Pyrolysis

Pilot-scale rotary kilns have helped US customers innovate in new energy, enabling them to successfu

Malaysian customers came to our factory to inspect the magnetron sputtering coating equipment

PECVD for carbon nanotube growth

Research group of Tsinghua University in China visited the factory

Professional Process, Effortless Purchase

Click to inquire

E-mail:web@kejiafurnace.com

E-mail:web@kejiafurnace.com

Tell:+(86) 18037178440

Tell:+(86) 18037178440

Whatapp:+(86) 180-3717-8440

Whatapp:+(86) 180-3717-8440

Address:Room 1505, Building 9, No. 26 Dongqing Street, Zhengzhou High-tech Industrial Development Zone

Address:Room 1505, Building 9, No. 26 Dongqing Street, Zhengzhou High-tech Industrial Development Zone

Tel Number

180-3717-8440

web@kejiafurnace.com

YouTuBe