Tel Number

180-3717-8440

Company Statement" Zhengzhou KJ Technology Co., Ltd. " belongs to the international business department of KJ Group. Starting today, the company will continue the international business contract signed or currently being performed by " Zhengzhou Kejia Furnace Co., Ltd. " See details >>

Description:

It’s mainly used for the preparation of rare earth, electronic lighting, crystal annealing, bio ceramics, electronic ceramics, special alloys, magnetic materials, precision casting, metal heat treatment and other industrial vacuum sintering, protective at

| Tube furnace part | |

| Model | KJ-1200T |

| Display | LED |

| Max. Temp. | 1200C |

| Working Temp. | ≤1100℃ |

| Heating Rate | Suggestion 0~10℃/min(max. 20℃/min) |

| Temperature Zone | 200mm+200mm+200mm |

| Temperature Control Accuracy | ±1℃ |

| Tube Size | Φ50mm x 1200mm (OD x L) Can be customized according to customer needs |

| Heating Element | Fe-Cr-Al Alloy doped by Mo |

| Thermocouple | N Type |

| Temperature Control | PID automatic control via SCR power control |

| Heating curves | 30 steps programmable |

| Chamber material | Alumina Fiber |

| Warranty | One year limited warranty (Consumable parts such as heating elements are not covered by the warranty) |

| Pressure Regulation System | |

| One mass flow meter | Which can regulate according to pump pressure  |

| pressure sensor |

(inficon brand: measuring range:3.8x10-5 to 1125 Torr ) installed on outlet of furnace tube.  |

| Touch Screen PLC Controller | Regulate pressure from 50-300torr |

| Notice: | The regulate pressure is under furnace in horizontal direction. The result maybe different in vertical direction. |

| Pirani Vacuum Gauge | |

|

Installed on gas inlet side of furnace tube Measuring range: 1×105~1×10-1Pa |

| 4 Channels MFC Gas Mixing Station | |

| Display | LCD Touch Screen |

| Working Temperature | 5~45 ºC |

| Max. Pressure: | 3x106 Pa |

| Accuracy: | ±1.5% FS |

| Liner | ±(0.5-1.5)%F.S. |

| Duplicate accuracy: | ±0.2%F.S. |

| Structure | Four precision mass flow meters: MFC 1: Flow range from 0~600 sccm for Ar MFC 2: Flow range from 0~600 sccm for N2 MFC3: Flow rang from 0~600 sccm for forming gas (5%H2+95%N2) MFC4: Oxygen:0-600sccm One gas mixing tank is installed on bottom case 5 stainless steel needle valves is installed on left side of bottom case to control 4 type gases mixing manually. |

| Pls note | Liquid or corrosion not supported. |

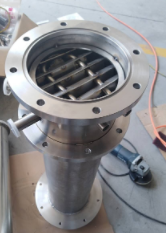

| Reference Photo: |   |

| Scroll Vacuum Pump |  |

| Nominal Rotation Speed | 1800 rpm |

| Displacement | 3L/S |

| Ultimate Vacuum | 0.008mbar |

| Noise Level | 54dBA |

| Inlet Flange | NW 25 |

| Exhaust Flange | NW 25 |

| Max Water Vapour Pumping Rate | 100 gh-1 |

| Leak Tightness | < 1×10-6mbar·l/s |

| Cooling System | Air cooled |

| Operating Temperature | 10 to 40℃ |

| The cart, bellow and clamp are included for one pump. |  |

| Cold Trap | |

| Cold Trap | Customized model,need to cooperate with water chiller |

| Water Chiller |  |

| Cooling Capacity | 1000W |

| Refrigerant Type | R134a |

| Precision | ± 0.3℃ |

| Pump Power | 0.03 kW |

| Max. Lift | 8M |

| Flow | 10L/min |

| Tank Capacity | 7L |

| Inlet and Outlet | Internal Φ8mm speedy connector Pagoda-shape connectors |

| Control Type | Digital Display |

| VIII Filter | |

| Used in the inlet of vacuum pump |  |

Rotary Tube Pyrolysis Furnace - For Engineering Plastic Pyrolysis

Pilot-scale rotary kilns have helped US customers innovate in new energy, enabling them to successfu

Malaysian customers came to our factory to inspect the magnetron sputtering coating equipment

PECVD for carbon nanotube growth

Research group of Tsinghua University in China visited the factory

Professional Process, Effortless Purchase

Click to inquire

E-mail:web@kejiafurnace.com

E-mail:web@kejiafurnace.com

Tell:+(86) 18037178440

Tell:+(86) 18037178440

Whatapp:+(86) 180-3717-8440

Whatapp:+(86) 180-3717-8440

Address:Room 1505, Building 9, No. 26 Dongqing Street, Zhengzhou High-tech Industrial Development Zone

Address:Room 1505, Building 9, No. 26 Dongqing Street, Zhengzhou High-tech Industrial Development Zone

Tel Number

180-3717-8440

web@kejiafurnace.com

YouTuBe