Tel Number

180-3717-8440

Company Statement" Zhengzhou KJ Technology Co., Ltd. " belongs to the international business department of KJ Group. Starting today, the company will continue the international business contract signed or currently being performed by " Zhengzhou Kejia Furnace Co., Ltd. " See details >>

Description:

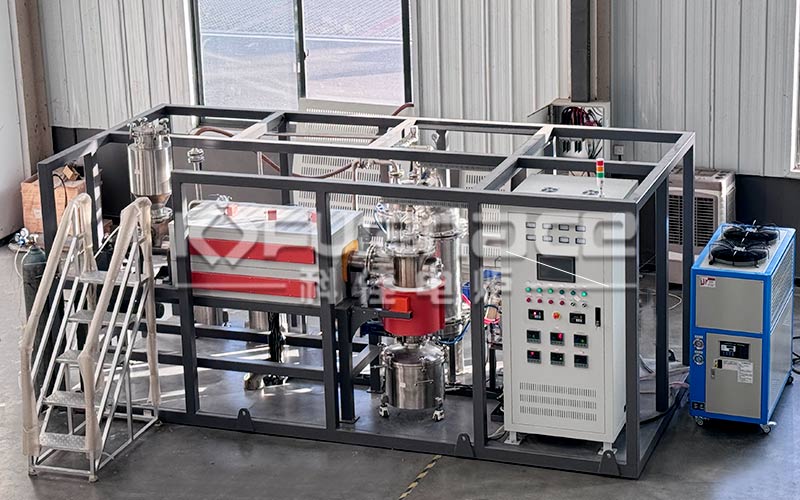

The continuous biomass pyrolysis laboratory apparatus is designed to test the pyrolysis process of different kinds of biomass raw materials. It consists of Control Cabinet, Raw Material Feeder, Pyrolysis Reactor, Syn-gas Burning Device, Gas Sampling Inter

The equipment is adopted with PID intelligent temperature controlling & monitoring system, which makes sure the precise and best reacting temperature;

The specialized control cabinet enables simple operation & adjustment;

Accessible Gas Sampling: It is convenient to collect the syngas through the special designed syngas sampler at Sampling Interfaces. Including syngas burners, and flame temperature detector.

Modular design contributes to minimizing clients’ installation and commissioning work. Before delivery, all of the mechanical and electrical components will be mounted on specially designed operation platform.

Optional Syngas Online Monitoring and Analysis Module enables the researcher to gain complete data of synthetic gas, such as composition, proportion, thermal value, etc., and to graph dynamic data curves. Detectable gas range: CO, CH4, H2, CO2, N2, C2H6,

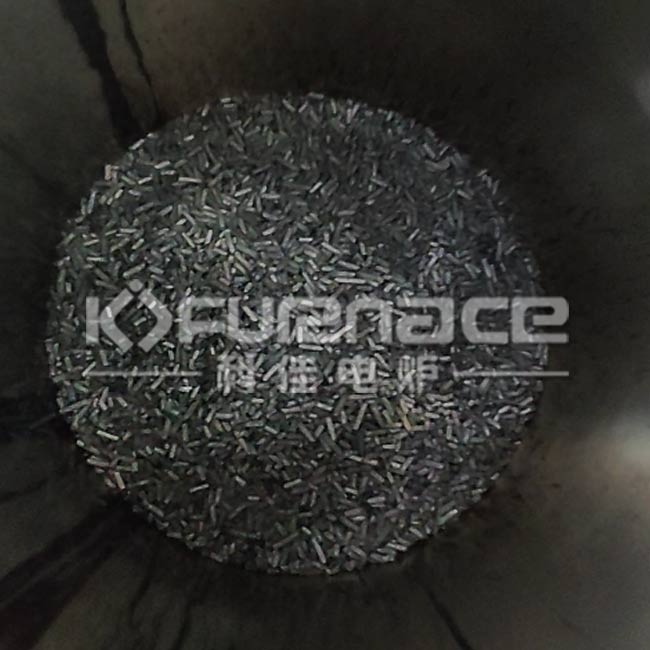

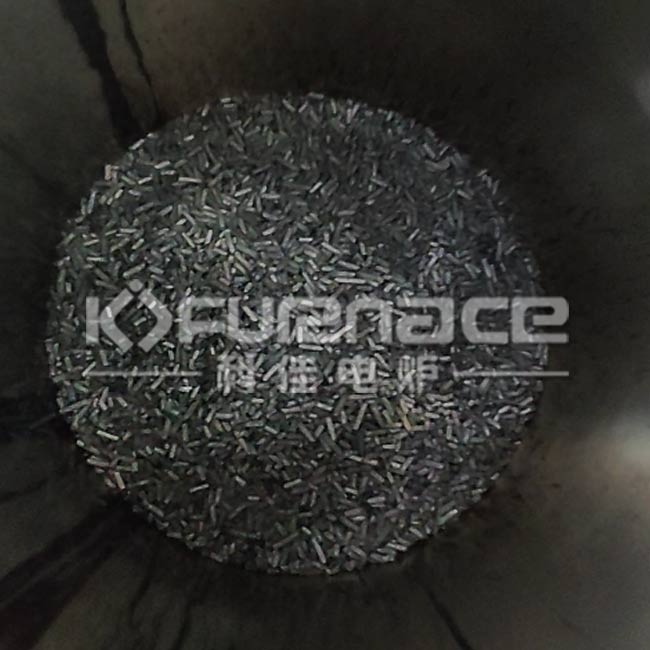

Biomass pyrolysis system can process materials: wood pellets, coconut shells, fruit shells, rice husk powder, bamboo charcoal, wood pellet charcoal, cocoa shells and other biomass materials. Welcome inquiry now.

Professional Process, Effortless Purchase

Click to inquire

E-mail:web@kejiafurnace.com

E-mail:web@kejiafurnace.com

Tell:+(86) 18037178440

Tell:+(86) 18037178440

Whatapp:+(86) 180-3717-8440

Whatapp:+(86) 180-3717-8440

Address:Room 1505, Building 9, No. 26 Dongqing Street, Zhengzhou High-tech Industrial Development Zone

Address:Room 1505, Building 9, No. 26 Dongqing Street, Zhengzhou High-tech Industrial Development Zone

Tel Number

180-3717-8440

web@kejiafurnace.com

YouTuBe