Tel Number

180-3717-8440

Company Statement" Zhengzhou KJ Technology Co., Ltd. " belongs to the international business department of KJ Group. Starting today, the company will continue the international business contract signed or currently being performed by " Zhengzhou Kejia Furnace Co., Ltd. " See details >>

Description:

This furnace adopts vertical structure, top discharge, graphite heating, and periodic operation. It is suitable for sintering metal powder, inorganic non-metallic materials, etc. under vacuum and high temperature. Of course, it can also be sintered under

| Model | KJ-VS-2200-1.6CLG |

| Furnace Part | |

| Display |

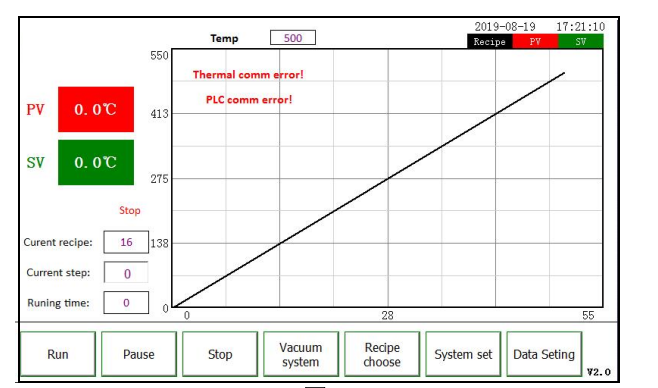

Touch Screen-7” LCD touch screen can operate both furnace and vacuum pump systems.

|

| Body structure | Double Layer steel casting support water jacket |

| Furnace shell | High intensity carbon steel with electrostatic spraying |

| Furnace chamber | Graphite |

| Max temp. | 2300℃ |

| Working temp. | <=2200℃ |

| Heating rate | Suggest 10℃/min(≤1600℃),5℃/min(1600℃-2200℃) |

| Heating elements | Graphite |

| Chamber size | 200*200mm(Diameter*Height) |

| Temperature control accuracy | +/-1℃ |

| Temperature Control | The temperature control system adopts artificial intelligence adjustment technology, with PID adjustment and self-tuning functions 1. Using PID mode to adjust temperature control, 30 sections of heating and cooling programs can be set 2. Temperature control accuracy ±1ºC 3, with over-temperature protection, broken couple protection 4. The instrument has the function of temperature self-tuning |

| Sealing method | Vacuum tank |

| Over-temperature alarm | Yes |

| Over-current protection | Yes |

| Thermocouple broken indication | Yes |

| Temperature measuring | Infrared temperature measurement |

| Suction mouth | 1 pc |

| Gas Outlet Port | 1 pc |

| Gas Inlet Port | 1 pc Support to insert protective gas( Micro pressure <=0.02mpa) |

| Vacuum Breaker | 1pc |

| Cooling Rate | Natural cooling |

| Vacuum System Part | |

| Max. Vacuum | 6.67x10-3Pa (Cool State) Kindly noted above vacuum is based on empty furnace |

| Vacuum Tank | Double layer water cooling carbon steel Silicone sealing device Hand wheel locking device |

| Vacuum system |

A vacuum pressure tank, rotary vacuum pump and diffusion pump with digital compact vacuum gauge |

Luxembourg XX well-known company in the field of coating purchases externally heated vacuum furnace

500℃ vacuum sintering furnace - for heat treatment of metal components

Deepening international cooperation, Russian customers visited and accepted the graphite vacuum furn

Pakistani customers visit Kejia Company

Jiangsu Taizhou Enterprise Customer Vacuum furnace for silicon carbide sintering

Professional Process, Effortless Purchase

Click to inquire

E-mail:web@kejiafurnace.com

E-mail:web@kejiafurnace.com

Tell:+(86) 18037178440

Tell:+(86) 18037178440

Whatapp:+(86) 180-3717-8440

Whatapp:+(86) 180-3717-8440

Address:Room 1505, Building 9, No. 26 Dongqing Street, Zhengzhou High-tech Industrial Development Zone

Address:Room 1505, Building 9, No. 26 Dongqing Street, Zhengzhou High-tech Industrial Development Zone

Tel Number

180-3717-8440

web@kejiafurnace.com

YouTuBe